EMU BLACK PLUG AND PLAY LOTUS 2ZZ

1,289.00€

Saadaval järeltellimisel

EMU BLACK Plug and Play Lotus 2ZZ

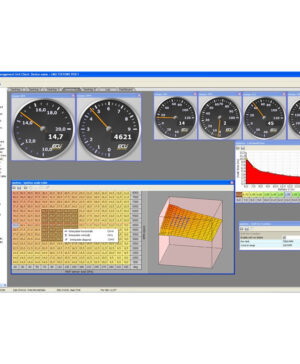

Ecumaster Plug In ECUs feature EMU Black technology in an OEMfitment enclosure for easy installation. Unlike Ecumaster Interconnectors, Plug In ECUs do not require a separate adapter. Asingle enclosure reduces complexity and installation time, and allows a stock base map to be pre-loaded. Plug In ECUs are housed in bespoke CNC aluminum enclosures that match OEM environmental ratings. Additional functions, such as extra inputs/outputs and lambda control, may be connected using an auxiliary harness.

SPECIFICATION

GENERAL

Temperature range – AECQ100 GRADE2 (-40 to +105˚C)

Reverse battery protection – Yes, internal

Operating voltage – 6-22V, immunity to transients according to ISO 7637

Enclosure – IP 60, custom CNC machined aluminium

Size (mm) and weight (g) – 150x72x31, 390

Connectors – 1 x 24, 1 x 39 FCI Automotive connector

PC communication – USB (with PC client software), serial, CAN

OUTPUTS

Injector outputs – 6 protected outputs 5A, low side

Ignition outputs – 6 outputs 7A(15A peak) (passive & active coils supported)

Aux outputs – 6 protected outputs 5A, low side

Other outputs – Full bridge up to 7A, can be used as separate outputs or 2 H-Bridges

WBO heater – Protected low side up to 5A

Communication – Serial, CAN BUS 2.0B

INPUTS

Analog inputs – 9 inputs, resolution 10Bits, 0-5V (protected)

EGT inputs – 2 for K-Type thermocouple

Knock sensor – 2 inputs

Oxygen sensor – LSU 4.2, LSU 4.9 or Narrow band

Trigger inputs – 3 (primary, 2 cams) Hall/ VR software selectable

VSS – 1 (Hall / VR)

Flex Fuel Sensor – Yes

Switch inputs – 3 inputs, switched to ground

SENSORS

Temperature sensors – IAT, CLT, Oil temperature, AC evap temperature

Pressure sensor – MAP, Oil pressure, Fuel pressure (user defined characteristic), AC pressure sensor, Back pressure

Oxygen sensor – LSU 4.2 or 4.9 (built in controller), Narrow band, external WBO controllers

Speed – Vehicle speed sensor (VR/HALL), Gear sensor (sensor, calculated)

FUELING

Injectors – SPECIFICATION Up to 8 HiZ injectors (sequential)

Injection angle control – 0-720 deg, start or end of injections

Battery compensation – User defined, wizard for popular injectors

Fueling strategies – VE based speed density, Alpha N

Air charge temp. – Based on IAT and CLT

VE table – 2 tables 16×20 (Load x RPM), resolution of 0.1%

Individual cylinder trim – Yes

Staged injection – Yes

Additional correction – Oxygen sensor corrections, EGT correction (per cylinder), BARO, TPS vs MAP, TPS vs RPM, Warmup, Nitrous, LC, ALS, ASE, Fuel pressure, Knock sensor

Lambda based real time correction – Using Lambda target table

Acc. / Deceleration enrichment – Yes

IGNITION

Ignition outputs – 6 for passive and active coils (software selectable)

Supported triggers – N-1, N-2, N-3, N+1, Multitooth, Subaru triggers, Nissan trigger, Lotus Elise, Audi trigger, Renault Clio Wiliams / Alpine, Colt 1.5CZ, Wrangler

Ignition angle table – 2 tables 16×20 (Load x RPM), resolution of 0.5 Deg

Per cylinder trim – Yes

Dwell time battery compensation – Used defined, wizard for popular coils

Odd fire compatibility – Application dependent

Additional correction – CLT, IAT, TPS vs MAP, Nitrous, Idle, Knock sensor, LC, Pit limiter, ALS, Flat shift, Timers, Acc. enrichment

KNOCK SENSING

Channels – 2

Resonant frequency range – 1-20kHz, 3rd order AAF

Sampling – Ignition event driven, knock window

Actions – Ignition retard, fuel enrichment, dashboard indication

IDLE CONTROL

Control type – PWM solenoids (2,3 wires), drive by wire, stepper motors (bi and unipolar), ignition cut, fuel cut

Control strategy – Open / Close loop , ignition angle control

VE correction – Yes, for Alpha-N

Corrections – AC clutch, coolant fan, analog input

BOOST CONTROL

Boost ref and target tables – 2 sets 10×10 (TPS vs RPM)

Control strategies – Open / Closed loop (PID based)

Corrections – Gear, VSS, IAT, EGT

DRIVE BY WIRE

Control strategy – Advanced 3D PID + static friction compensation

Supported throttles – All with DC motor and current requirement lower than 6.5A. Wizard for 28 popular electronic throttles

PPS to throttle position characteristic – 3D table

BLIP support – Yes

ALS support – Yes

TRACTION CONTROL

TC strategy – Delta RPM, gear compensation

Torque reduction – Spark cut using 3D table (16×20)

Sensitivity control – 10 position rotary switch

VARIABLE VALVE TIMING

Supported systems – VVTi, MiVec, VANOS, Double Vanos

Number of camshafts – 2

Control strategy – PID based closed loop, CAM angle target tables 12×12

FLEX FUEL

Ethanol content measurement – Yes

Fuel temperature measurement – Yes

Tables blending – VE, IGN, Lambda/AFR, Boost, Cranking fuel, ASE, Warmup

Fuel temperature PW correction – Yes

SPORT

ALS – 2 independent ALS setting, DBW support

Shift light – Per gear shift light

Launch control – Yes

Gear cut – Yes (Open loop), DBW blip supported Source: Switch, load cell, CAN

Pit limiter – Yes

Rolling anti lag – Yes

ENGINE PROTECTION

Fail safe values for critical sensors – Yes

Dashboard indication of failures – Yes, user defined

Over temperature engine protection – Yes (oil and coolant), user defined, RPM limit

Low oil pressure protection – Yes, user defined, shut off

Fuel pressure protection – Yes, fuel dose compensation, RPM limit, engine shut of

High exhaust temperature – Alarm, per cylinder fuel trim, boost limit

CAN BUS

CAN standard – CAN 2.0 A/B (125, 250, 500, 1000 kbps)

Supported CAN Dashes – ECUMASTER, Motec M800 Set 1, Haltech E8 E11v2, Pectel SQ 6, AEM

Supported OEM CAN streams – BMW E46, Citroen C2, Mazda RX8, Ford ST, Polaris RZR, Mini Cooper R53, Fiat 500, Renault Clio, Lotus, Ford Fiesta, Ford ST, EVO X (AYC support)

OTHER

Unused injection outputs can be used as AUX output – Yes

Output functions – Fuel pump, coolant fan, parametric outputs, nitrous control,PWM 3D table output, AC clutch, main relay, speedometer, tachometer

Password protection – Yes, 2 levels

Timers – Fuel, Ignition, Boost, timers controlled by virtual outputs

Serial dashboard support – AIM, RaceTechnology

Autotune – Yes

Built in trigger scope – Yes

Logging – RealtimeloggingtoPCcomputer,loggingonexternal loggers(serial/CAN)

DSG – DQ250,DQ500

VPF Heading

| Mark | Mudel | Aasta |

|---|---|---|

| Mark | Mudel | Aasta |

| BMW | 3 SERIES | E46 1997-2006 |

| Citroen | C2 | 2004-2010 |

Seotud tooted

Warning: Undefined variable $same_cat in /data03/virt70070/domeenid/www.carstyling24.ee/htdocs/wp-content/plugins/wp-nextprev-product-navigator/wp-next-prev-product-navigator.php on line 42

Warning: Undefined variable $same_cat in /data03/virt70070/domeenid/www.carstyling24.ee/htdocs/wp-content/plugins/wp-nextprev-product-navigator/wp-next-prev-product-navigator.php on line 43